Oil Free High Pressure Compressor ( Shark)best speed, best price, best quality

- oil-free, water-cooled, reciprocating compressor, 2 or 3 stage compression

- Through the use of PTFE piston rings and support rings, we can produce low pressure or high pressure oil-free compressor.

- Compressors are compressed in grades 2 or 3 and maintained in a reasonable range of temperatures.

- Each cylinder is equipped with the same number of suction valves and exhaust valves. The compressed air between each two stages is cooled to (40-60 DEG C), and the condensate is automatically discharged at regular intervals.

- The final exhaust pressure is controlled by an automatic control system.

| MODEL | BARE COMESSOR | AIR DELIVERY (m³/min) | PRESSURE (Mpa) | (r/min) | POWER(kw) |

|---|---|---|---|---|---|

| 61HLW-8.5/40 | HW08A | 8.5 | 4.0 | 460 | 90 |

| 61HLW-10/40 | HW08A | 10 | 4.0 | 500 | 110 |

| 61HLW-12/40 | HW08A | 12 | 4.0 | 580 | 132 |

| 58HLW-16/40 | HW12C | 16 | 4.0 | 400 | 160 |

| 58HLW-16/40 | HW12C | 18 | 4.0 | 420 | 185 |

| 58HLW-20/40 | HW12C | 20 | 4.0 | 470 | 200 |

| 58HLW-22/40 | HW12C | 22 | 4.0 | 500 | 220 |

| 60HLW-25/40 | HW22B | 25 | 4.0 | 370 | 250 |

| 60HLW-28/40 | HW22B | 28 | 4.0 | 420 | 280 |

| 60HLW-30/40 | HW22B | 30 | 4.0 | 450 | 315 |

| 61LW-10/10 | OFR100 | 10 | 1.0 | 500 | 75 |

Product Features

- COMPRESSED SERIES: 3 STAGE, LEVEL FOR DOUBLE-ACTING CYLINDER, SECONDARY AND TERTIARY SINGLE-ACTING CYLINDER.

- LONG STROKE LENGTH: IN THE SAME INDUSTRY 10% TO 30% OR MORE, CAN REALIZE LOW SPEED HIGH EFFICIENCY.

- SMALL PISTON FORCE: LONG STROKE, THE PISTON DIAMETER DECREASES , THE PISTON FORCE DECREASES.

- THREE STAGE OF THE EXHAUST TEMPERATURE IS 90 ℃ ~ 130 ℃, EXTEND THE SERVICE LIFE OF PISTON RING.

- THREE STAGE OF THE EXHAUST TEMPERATURE IS 90 ℃ ~ 130 ℃, EXTEND THE SERVICE LIFE OF PISTON RING.

- NUMBER OF PISTON RING: ADD 1 TO 3 RING AT EVERY STAGE, REDUCED THE LEAKAGE.

- THE SMALLEST VIBRATION: THE WEIGHT OF THE MOVING PARTS PRECISION CONTROL, REALIZED THE DYNAMIC BALANCE.

- THE SMALLEST VIBRATION: THE WEIGHT OF THE MOVING PARTS PRECISION CONTROL, REALIZED THE DYNAMIC BALANCE.

Boot step:

- Preparation: switch on the equipment power supply and switch on the low-pressure air source (0.6Mpa)

- Start cooling tower and external circulating pump

- Discharge air from the cooling water pipe of the compressor (including water pump)

- The electric control cabinet control switch (right to uninstall uninstall open position)

- Unscrew the red emergency stop button

- If there is a fault alarm, press the Yellow fault recovery button

- Press the green boot button

- The cabinet will switch to the left (unloading unloading control closed position)

- The machine will load automatically in 300 seconds

Shutdown procedure

- First, the right to control the switch cabinet unloading (unloading open position)Press the red stop button

- After a minute, make sure the motor stops spinning and then performs the following operations (remember)

- Turn off the air compressor power

- Close the low-pressure air source

- Stop cooling tower and pipe circulating pump

Emergency stop button usage: if abnormal situation occurs, emergency stop is necessary, emergency stop button can be used. The emergency stop button can only be used in the case of abnormal machines. If it is used frequently, it will cause damage to the moving parts of the machine.

Also, remember to cut off the power supply directly while the machine is running!!!

Special reminder: if a long time low temperature shutdown, the machine cooling water should be completely discharged, to prevent freezing!As before, the environment temperature are less than 10 or 0 DEG C if the weather is cool down, the machine cooling water thoroughly drained and prevent freezing!

Water: water quality, water pressure, water temperature

Power: voltage, wiring

0.6-0.8MpaGas: low pressure control gas 0.6-0.8Mpa

Wind: ventilated, clean

Oil: oil quality, oil pressure, oil temperature

- PLC parameters are not allowed to change freely.

- regular replacement of circulating water and cleaning Y filter.

- The water temperature of the 3 and two stage cylinders is between 40 and 50.

- to ensure that two automatic discharge valve (corner valve) work properly.

- Do daily record and archive. (very important!)

- 每Every shift shall be discharged from condensate tank and related equipment and containers.

- regular replacement of lubricating oil and oil filter, the cycle is about 3~6 months to replace.

- check the tightness of the cabinet wiring, clean up dust.

- regularly check the belt tightness.

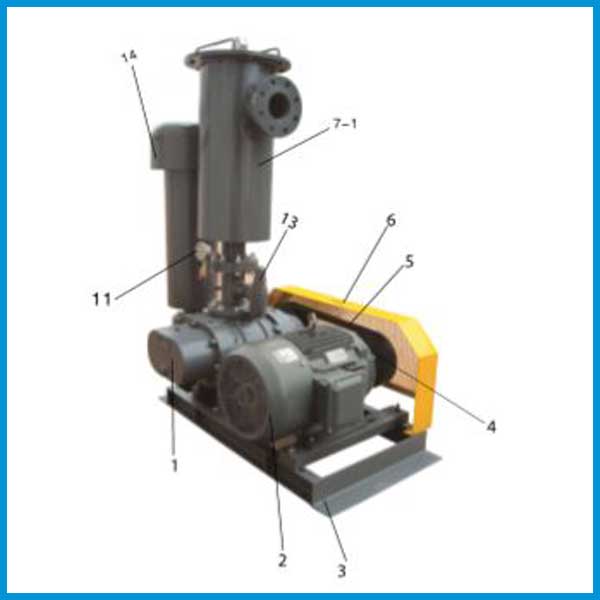

① PISTON, PISTON RING

② PACKING

③ OIL SCRAPER RING

④ INLET VALVE, UNLOADING DEVICE

⑤ EXHAUST VALVE

⑥ CYLINDER

⑦ CYLINDER HEAD

⑧ IN THE INDRECT CANISTER(GUIDE-CROSSHEAD)

⑨ FUSELAGE

⑩ CRANKSHAFT,CONNECTING ROD, CROSSHEAD