Pet Machine (King Machine)best speed, best price, best quality

Pet Machine (King Machine)

Zhangjiagang king machine Co., Ltd is located at the new port city -zhangjiagang ,was founded at 1995,and starting with beverage machinery.Our company have fixed assets over RMB 30million and covers an area of 20000m2,We are a leading enterprise in research and production of liquid food and beverage packing and filling industry .our Main products including: Pure/mineral water and purified water producing line. carbonated beverage producing line. 3gallons& 5gallons producing line. Flat and tube UHT device, and CIP system.All the products are sold well in every province and city of the whole country and also exported to about thirty countries and areas with strong technical force, advanced equipment, scientific management system and perfect after-sales service.

Certificates :

Successful Stories:

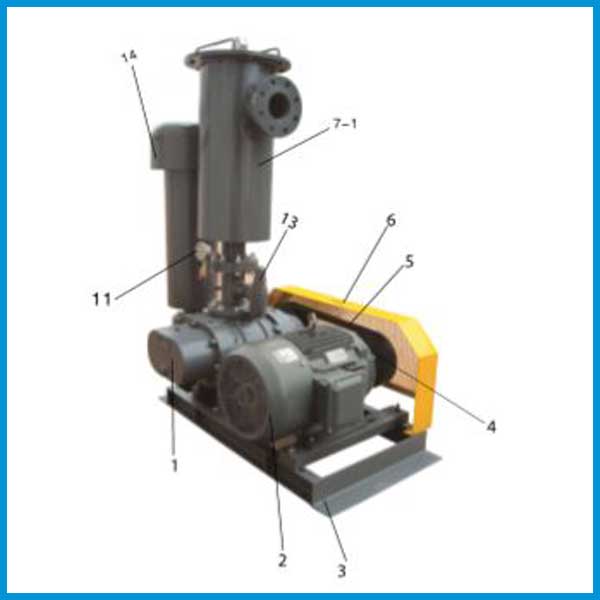

Parameter (Pictures only for your reference)

1. LX-9E electric servo motor automatic PET bottle blowing machine

Technical Parameter of blow molding machine

| Item | LX-9E | |

|---|---|---|

| Main machine | Maximum Bottle capacity | 700ml |

| Maximum bottle diameter | Φ68mm | |

| Neck diameter | Φ18~38mm | |

| Maximum bottle hight under neck | <240mm | |

| Maximum preform height under neck | <115mm | |

| Clamping stroke | 90mm | |

| Bottom die stroke | 50mm | |

| Bottle pitch | 76.2mm | |

| Maximum output rate(bph) | 12000(500ml water bottle) | |

| Number of molds | 9 | |

| Heating part | Number of heating modules | 6 |

| Number of heating lamps | 8 | |

| Number of preform bases | 132 | |

| Voltage | 380v | |

| Electric par | Frequency | 50/60Hz |

| Service power | 40~60kw/h | |

| Installation power | 110kw | |

| Air source (High pressure air consumption depends on PET bottle volume) | Low preasure | 1Mpa |

| Low pressure air consumption | 2m³/min | |

| High pressure | 3.5Mpa | |

| High pressure air consumption | 8m³/min | |

| Cooling water | Presure | 2~4bar |

| Cooling water(≤18℃) | Flux | 9m³/h |

| Weight | G.W. | Around 9000kg |

| Dimesion | Main machine(L×W×H) | 5600×2600×2400mm |

| Preform unscrambler(L×W×H) | 4500×3500×3500mm |

Main Component list

| No | Name | Origin | Brand |

|---|---|---|---|

| Electric/control component | |||

| 1 | Air switch | France | SCHNEIDER (TE) |

| 2 | Intermediate relay | Japan | OMRON |

| 3 | Contactor | ||

| 4 | Button | ||

| 5 | Touch screen | ||

| 6 | PLC | ||

| 7 | Motion actuator | ||

| 8 | Servo motor | ||

| 9 | Servo actuator | ||

| Valves/adaptor | |||

| 1 | 1st stage blowing valve | USA | PARKER |

| 2 | 2nd stage blowing valve | ||

| 3 | Exhaust Valve | ||

| 4 | One-way valve | ||

| 5 | Pressurize clmaping valve | ||

| 6 | Cylinder control valve | UK | NORGREN |

| 7 | Step chain | Taiwan | KMC |

| 8 | Mold-closing slide-way | Taiwan | ABBA |

Feature New Auto Preform Unscrambler System

- Adopts one-way preform-feeding structure and preform-separating by servo motor structure which solve the preform bloc k and abrasion problem.

- There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder that will warn the operator to add the preforms into the hopper when lacks preform instead of stopping the machine.

New Heating System

- Perfect heating system design decrease power consumption.

- Special oven design helps power saving and easy maintain.

- Each lamp position and temperature can be adjusted.

- Cycle air-cooling system keeps the oven temperature constantly.

The Application Of Servo System On Main Transmission

The transmission adopts servomotor for positioning that can orientate the preform-heating base quickly, accurately and ste adily when the machine starts and running.

Servo Technology Innovation On Clamping System & Stretching

- Adopts servo motor to drive the two cranks to control the clamping system which can shorten the mold-clamping time and improve productivity, and also solve the swelling mold and big joint line problem with the effect of pressurize plate.

- Servo motor using for stretching to ensure the bottle blowing speed faster and more stable bottle quality.

1.5 Easy To Change Bottle Shape

- Drawer type mold structure design is easy for mold changing. Within one hour can change a mold on the condition of same bottleneck diameter.

1.6 Intelligent Human-Machine Interface

- Human-machine interface control, easy operate and monitor.

- Live production information supervise, auto record production data everyday

- Failure warning and troubleshooting.

Appendix

I) Installation, debug, training, after sales

(One.)installation, debug

After equipments reached the workshop of customer, place the equipments according to plane layout we offered. We will arrange seasoned technician for equipments installation, debug and test production at the same time make the equipments reach the rated producing capacity of the line. The buyer need to supply the round tickets and accommodation of our engineer, and 100 USD per day as the salary for one engineer. (

(Two.) training

Our company offer technology training to customer. The content of training is structure and maintenance of equipments, control and operation of equipments. Training is in the workshop of customer. Seasoned technician will guide and establish training outline. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

(Three.) Quality guarantee

We promise that our goods are all new and not used. They’re made of suitable material, adopt new design. The quality, specification and function all meet the demand of contract. We promise that the products of this line could storage for one year without adding any aseptic.

(Four.) After sales

- after checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipments according to seller’s demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician.

- after quality guarantee, we offer technology support and after sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipments according to seller’s demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician.

(II) Check & accept of equipments

(Equipments supplied by our company, we will offer products quality guarantee and test report)

- check & accept standard(bottles and caps should be eligible)

- working efficiency of the whole line ≥85%

- The quantity of waster of the whole line ≦0.2%

- Bottle leakage: invert the bottle and press by hand come forth water leakage

- Without cap, crooked cap or cap with damage

- Clip bottle bad or damage the bottle seriously

- the whole line will run continuously for 8 hours, stable quantity of the average acceptable-end products≧99%

- the distance between the material inside the bottle and the top of bottle neck is less than 8mm (full after cooling)

- the liquid reflux ﹤10%

- the sanitation of the product meets the standard of beverage industry.

- about the checking and accepting of animalcule will carry sample and check according to the standard of nation beverage industry, the result of checking will according to the request of industry standard.

2. Check & accept procedure

- After debugging the machine in seller’s factory, after checking out and signature of two sides, then we can shipping the machine.

Finish installation and debugging the machine, after checking out, Running the whole production line to show the line function, after certification then final checking. Meanwhile training for operation, maintenance and so on, then make a signature of two sides to become effective.

(III) Supply, installation, debug time

- Valid time of the prices: 90 days.

- Time of equipments production:45 days.

- Time of installation and debug:7 days.

- Payment terms: 30% as down payment, 70% before shipment. T/T or L/C.

- Guarantee time: 12 months after machines running in buyer’s factory.

(IV) Package and transport

- Package type As usual, we adopt wooden case as package type. It’s suitable for long-distance transport. According to customers’ special demand, we could adopt sheet iron case and so on.

- Transport By sea.

(V) Certificates